Make a lamp that charges your watch and holds your phone.

Forewarning

This project is a little more advanced than your basic pipe lamp when it comes to wiring. I'm not saying you should let that stop you--you can borrow a competent friend for assembly; however, someone needs to be aware of the difference between ground, hot, load, neutral etc. and the implications of getting these things wrong. Also, please don't forget to unplug your creation before servicing it in anyway.

Picking your parts

Box

I used a double gang electrical box with plenty of knock outs. Consider that some boxes have knockouts that can be 1/2" or 3/4" which is pretty convenient. In theory, you could make this work with a single or triple gang box. You could even use an octagonal box if you can find the right face for it.

Pipe

Another place you can get creative is in the pipe. There's black pipe, galvanized pipe, brass fittings, and even copper or PVC. Assembly for copper and PVC would be a bit different though. You could use conduit fittings as well. You can see I used black pipe exclusively but, with some exploring at the hardware store, you can often get different types of fittings to mate up well enough. We're not making something weatherproof here.

When it comes to the size of your pipe, you'll want to pay attention to which knockouts you plan on using in your box. My box has 1/2" and 3/4" knockouts but I only used the 3/4" ones.

For reference, I used these fittings in 3/4":

- 2x 45° FPT to MPT street elbows: where the two arms come out

- 2x 90° FPT to MPT street elbows: where the legs attach to the "hip"

- 1x 90° FPT street elbow: to support the watch charger

- 1x FPT Tee: for the "hip"

- 1x 3" pipe: from the "hip" to the box

- 2x 4" pipes: for the legs

- 2x caps: for the "feet"

- 1x 3/4" to 1/2" reducer: for the lamp holder

Lamp Holder

You can see I went with a simple,

gray lamp holder. You can get these in a variety of colors or you could use a different style but these can connect nicely with 1/2" knockouts in your box. In my case, the knockout I wanted to use was 3/4" only so I used a black pipe to adapt from 3/4" to 1/2".

Bulb Considerations

I love the "Edison" style bulbs. If you live in a warm area like I do and are concerned out the heat given off, you might want want to go with an

LED one. These are more expensive and generally don't look as interesting as their

incandescent equivalents but they use less power too. On the other hand, the LED ones have their own flare.

Edison Style LED Bulb

Edison Style LED Bulb

Edison Style Incandescent Bulb

Phone Holder

I really like the

X-Grip by RAM. These have gotten pretty expensive since I first started using them. Another holder I think would look great here is the iBOLT

Roadvise. If you want your phone-holding arm to be fairly articulating, you'll also want to get a socket arm. In my next such project, I think I might use one of these

composite socket swivel arms.

Another approach is to simply put several high power,

neodymium magnets back to back and put a

slim metal plate in your case or on the back of your phone. I have this in my car so I just place my phone on the magnet and it stays--even off-road. When I'm getting out of the car, I just grab it. For this little guy, I felt the X-Grip added a nice "hand"-iness to the look.

Outlet

You will probably want an outlet with USB ports and A/C outlets, if you plan on being able to plug in other chargers. I recommend the Decora style for simplicity in getting a plate.

This is the one pictured.

Switch

I wanted something with a dimmer and I like light switches that have a subtle light on them when the switch is off to make them easy to find in the dark. Again, I recommend the Decora style for simplicity in getting a plate.

This is the switch I used.

Wall Plate

I went with a Decora style brushed metal wall plate.

Wire & Wire Nuts

You'll need some basic wire and wire nuts. Solid wire works better with wire nuts and connecting to fixtures in my opinion but I got

stranded for general use.

Power Cord

Don't forget, you'll want a grounded--that is a 3 conductor--cord. You can't get away with a 2 conductor like you could on your basic lamp. I like this

cord because of the vintage cloth wrap.

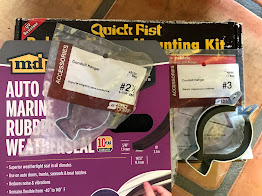

Squeeze Connector and Nuts

I used a

squeeze connector to get my power cord into my box. There are other styles. The sizing on these seems to not be as simple as everything else. Make sure you get the size you need or buy a couple if in doubt--that's what I do.

Halex lock nuts. These need to match the size of your pipe where it enters your knock-outs. I used a lot of these. 8 to be precise. See assembly below.

USB Cords

I went with the braided cords because I thought they brought a little something. This

4ft red lighting cable because of how it stands out. For the watch charger, it was tough to find a short, braided one that worked.

This is what I ended up with.

Bottle Caps & Magnets

To attach the watch charger, I used a bottle cap and 1" magnets. I'm not a fan of glue but a glue gun would certainly be an option.

Assembly

Attaching your Pipes to the Box

Short of the wiring, most of this goes together very intuitively and you don't have to run wire through pipe so that's plus; however, the big trick for me was getting these heavy pipes to attach snugly without protruding more than couple mm or so into the box. Simple, conventional outlets and switches are pretty slim; however, an outlet with the hardware to run some USB plugs gets chunky and a dimmable light switch is much the same--bulky.

You'll find you have little room between the fixtures and the walls of the box and not much room for the pipe to be attached. I used Halex nuts threaded minimally on the inside of the box and then another one tightened from the outside. Make sure these are tight and the exterior pipe mostly at the desired angles. You won't have any room to tighten them from the inside once the outlet and switch are attached to the box.

Fixtures and Wiring

Attach your squeeze connector and lamp assembly before putting in your fixtures.

Next, I recommend bringing in your power cord through the squeeze connector and wiring everything up with the wire nuts.

Attach your fixtures to the box and then tighten your squeeze connector.

Now you can put on your wall plate.

Watch Charging Support "Hand"

I used a bottle cap with two 1" diameter magnets to make the watch charger easily removable. You could use a glue gun instead.

To attach my bottle cap to the street elbow, I flared out the edges of the cap in 3 places until it threaded into the street elbow. Let me be clear: this wasn't easy to get just right and took several attempts.

Final Assembly

- Thread on your watch charger holding arm.

- Attach your phone holder.

- Put in your light bulb.

- Hook up your USB cords.

Now, check out your creation.